TIPS FOR ELECTROFUSION WELDING

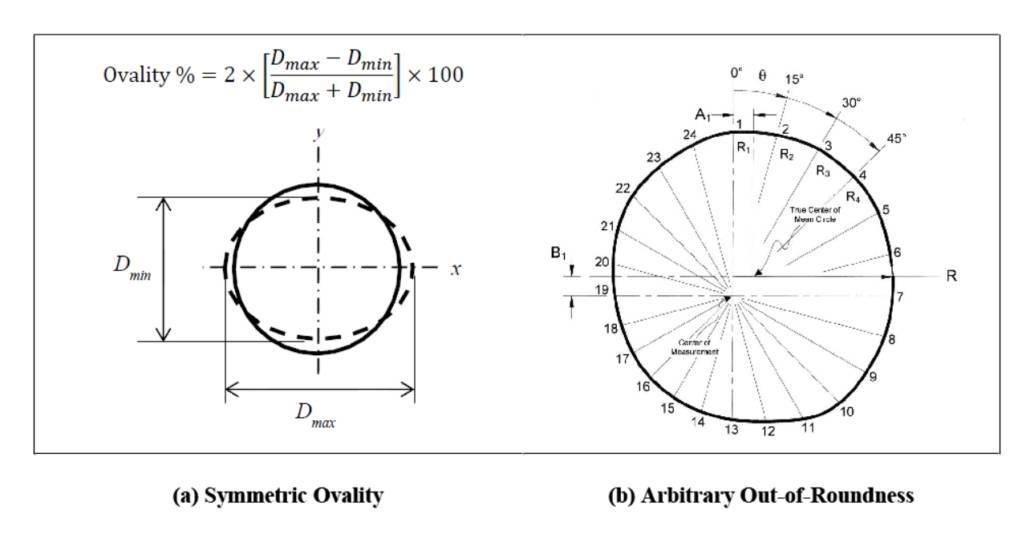

The non-brittle and flexible characteristics of polyethylene make it ideal for many pressure and non-pressure applications. Those useful characteristics also mean PE pipe can alter shape. Ovality generally known as ‘out of roundness’ is one of the most common issues found in PE pipe. One of the best tips to ensure a quality electrofusion weld is to ensure that polyethylene pipe is not out-of-round before attempting the electrofusion process.

To determine if out-of-round conditions exists measure the pipe diameter in numerous directions across the pipe end with a tape measure. If the measurements exceed the maximum tolerance, a re-rounding clamp or device must be used to bring the pipe back to a round condition.

HOW DOES POLYETHYLENE PIPE BECOME OUT-OF-ROUND?

MANUFACTURING

Installers need to confirm that polyethylene pipe matches all dimensional requirements for the job and the fitting being installed and that the pipe does not exceed the allowed ovality. If ovality is greater than allowed you must take steps to re-round the pipe.

STORAGE

Polyethylene pipe that is warehoused for a period of time or stacked on top of each other can experience ovality issues (more pronounced with large diameter pipe).

TIME

Large Diameter Polyethylene pipe will tend to relax a little during storage due to a combination of its weight and its natural flexibility.

INSTALLATION

Mechanical forces experienced during some trenchless installation techniques such as Pipe Bursting or Directional Drilling can temporarily leave the polyethylene pipe elongated and out-of-round.

PREVIOUS INSTALLATION

Polyethylene pipe that has been underground for awhile is subjected to earth loads. These earth loads can cause the pipe to sag and/or become out-of-round.

WHY IT IS KEY TO ADDRESS PIPE OVALITY FOR ELECTROFUSION INSTALLATIONS

One of the most critical functions of the electrofusion process is to seal the gap between the pipe and the fitting and to build up interfacial pressures for the fusion process to take place. If this gap is not sealed and interfacial pressures cannot build up, there is no way for the electrofusion joint to effectively achieve the high quality fusion it was designed for.

If a pipe is out-of-round the initial concern is that the surface area of the pipe may not adequately come in contact with the fusion zone of the electrofusion fitting. This could result in the electrofusion fittings cold zones, which are designed to contain the material generated in the melt pool, allowing the molten material to escape out of the fusion area without producing any melt penetration. This is a key concern when installing tapping and branch saddles since they do not fully encircle the pipe like an electrofusion coupling.

HOW TO CORRECT OUT-OF-ROUND PIPE

First, determine if out-of-round conditions exists. This can be done visually for extreme cases or by measuring the pipe diameter in numerous directions across the pipe end with a tape measure. If the measurements exceed the maximum tolerance, a re-rounding clamp or device must be used to bring the pipe back to a round condition.

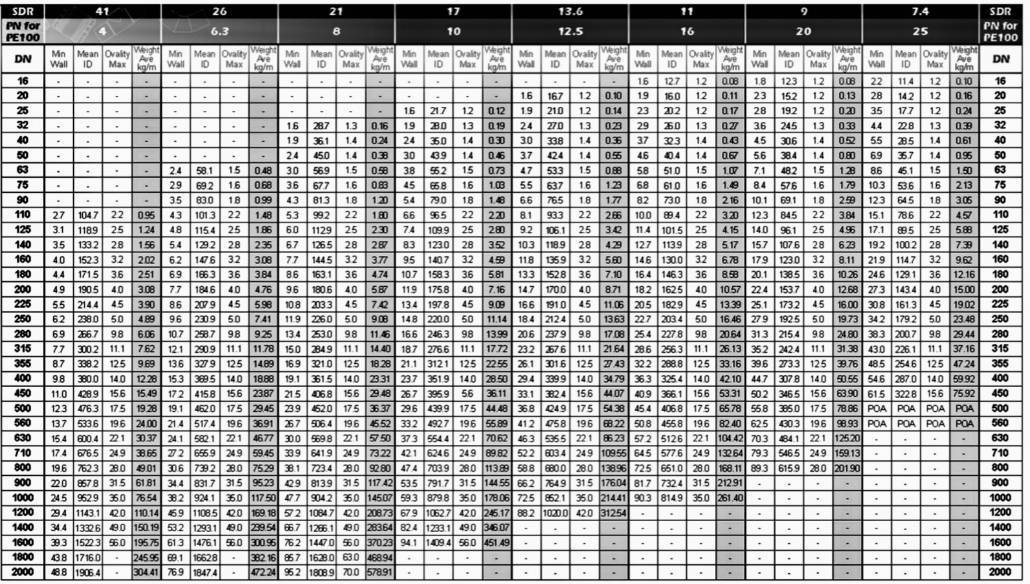

The following table shows the approved dimensions for PE100 pipe:

The PLASSON range includes high quality tools to prepare pipe correctly for electrofusion, inlcuding re-rounding clamps. Click here to see PLASSON’s tooling range….