SIMPLY SMARTER ELECTROFUSION

THE SMARTFUSE DIFFERENCE

PLASSON has been manufacturing innovative electrofusion fittings for decades. The SmartFuse system brings together the best electrofusion fittings and a systemised installation and weld recording process.

All SmartFuse fittings have smart resistors built in that feed the correct weld parameters into PLASSON’s SmartFuse EF welders as soon as the fitting is connected.

No manual entry and no scanning means it’s not only faster to set up each and every weld but the potential for costly input errors is eliminated.

The SmartFuse system is designed to guide each weld so that installers have clear steps to follow and there are prompts to ensure stages are fully completed.

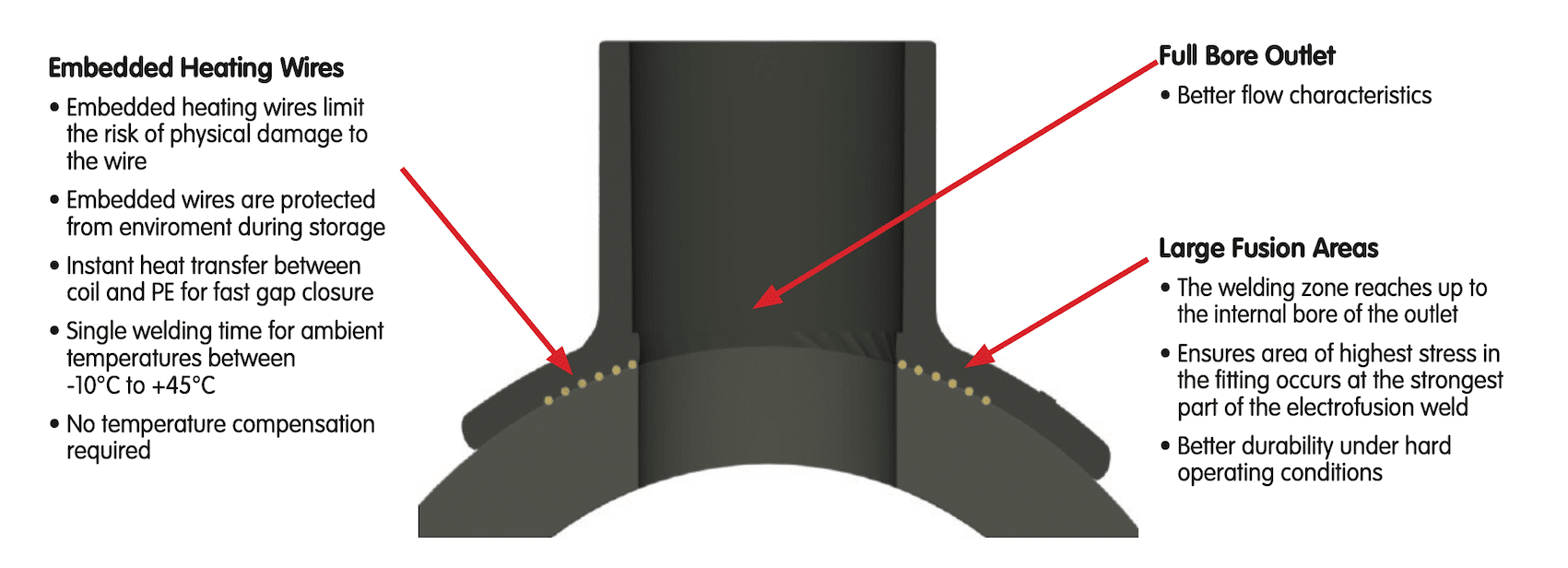

ADVANCED ELECTROFUSION FITTINGS

Electrofusion fittings have different weld parameters and SmartFuse fittings have built-in resistors that feed these details directly into PLASSON’s SmartFuse control boxes.

The SmartFuse mobile app is also designed to make every job easier with guided installation, weld recording and reporting. Through the app, installers are not only guided through systemised welds, the app records photographs of each step.

Visual records are stored along with details for the fitting, precise location, installer ID, all control box weld stage times and data.

This data can be saved on site via USB, which is handy in remote areas with limited internet access, or automatically in the cloud. This gives managers and asset owners a real-time comprehensive picture of what is happening on any job, anywhere, anytime

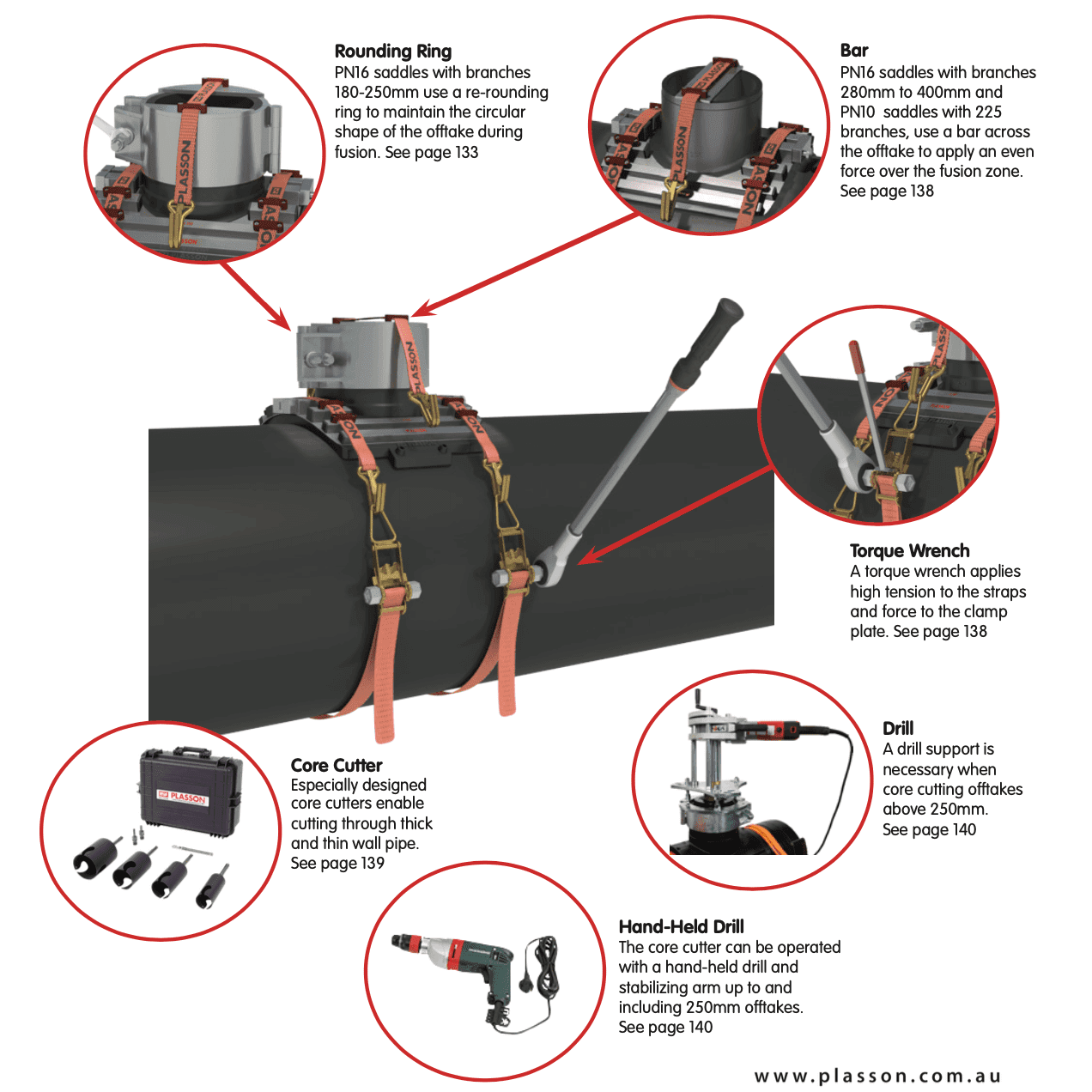

LARGE BORE BRANCH SADDLES

Large diameter EF fittings require heavy-duty controllers and generators to supply the necessary power for long weld times. This high load means the control box will need to cool between welding cycles.

For those jobs where time is crititcal, PLASSON has developed a new controller called the PolyControl Plus. With built-in cooling and novel power transformer technology, the PolyControl Plus reduces time between welds to a minimum.