LOOKING FOR TIPS ON EF WELDING?

Are you searching for electrofusion welding tips? Looking for that magic piece of advice wrapped up in an easy to watch video? Well, the good news is you’ve come to the right place!

The hot tips to achieving good EF welds are summed up by two simple words: “precision” and “accuracy”. Whether you are installing a 16mm coupler or a 1000mm fitting, here’s the best electrofusion tip there is… give full attention to precision and accuracy at every step of the process.

Quality electrofusion welds are literally built on precision (being exact) AND accuracy (being correct).

“Precision” is about instruments and their parameters.

As an example, vernier calipers will measure precise peel depth during pipe prep down to 0.02 mm. A metal rule is precise to 1 mm. That makes it perfect for witness marks but rules (!) it out for gauging precise peel depth.

Here is where “accuracy” steps in – the correct tool used correctly.

PLASSON created the SmartFuse EF system to deliver a framework that supports the precision and accuracy required for successful electrofusion welding.

This system includes smart fittings with accurate welding parameters preloaded into each fitting, reliable, robust welding control boxes which automatically detect weld parameters for SmartFuse fittings and a mobile app to guide installers through each weld and record key details, like GPS location, fitting type and barcode, for easy downstream management.

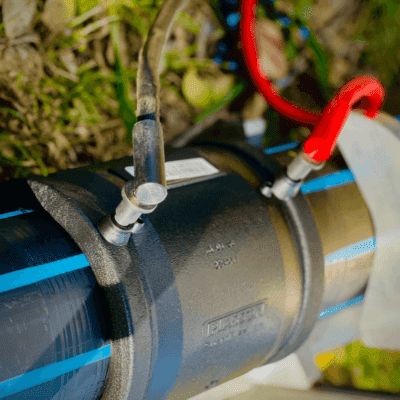

SmartFuse fittings have resistors that feed accurate weld parameters to the SmartFuse control box once the fitting is connected.

No manual entry and no scanning means it is not only faster to set up each and every weld but the potential for inaccurate input errors is eliminated.

The SmartFuse mobile app also helps make the welding process more accurate and precise. When using the app, installers are not only guided through systemised welds, the app ensures installers double-check and confirm all details and record photos of each step. These visual records are stored along with details for the fitting being installed, the precise location, the installer’s ID, all control box weld stage times and data and even the temperature on the day!

This data can be saved on site via USB, which is handy in remote areas with limited internet access, or automatically in the cloud. This gives managers and asset owners a real-time comprehensive picture of what is happening on any job, anywhere, anytime

SIMPLIFYING WELDS

Weld times for PLASSON fittings are specific to the type of fitting. This is automatically detected by the SmartFuse control box.

Once welding and the required cool down time is complete, the fitting and the pipe are permanently fused together. The result is a water-tight and gas-tight connection.

Using this system means all weld parameters are preset and controlled ensuring safe, dependable welds. With the entire process automatically recorded, contractor certification and record keeping is one less thing to worry about.

The SmartFuse system is designed to guide each weld so that installers have clear steps to follow and there are prompts to ensure stages are fully completed.

The use of the SmartFuse system does not remove the requirement for EF installers to be certified.

SmartFuse is designed to support certified electrofusion installers to work efficiently and accurately as well as helping by automatically recording detailed weld data for future reference.

See how SmartFuse fittings and welding control boxes work in this handy demo video:

SmartFuse fittings have resistors built in that automatically send the correct weld settings to the SmartFuse control box when connected.

It is also possible to load the weld parameters via barcode scanner on some fittings. The SmartFuse control box will guide operators through the entire welding process.

When also using the SmartFuse app, the weld data, GPS location and photographs of all weld steps are recorded and can be stored in the cloud for easy reference.

PIPA – the Plastics Industry Pipe Association of Australia – has created electrofusion industry guidelines, called POP001.

This document outlines the precison tools, accurate measurements and correct procedures (Best Practice) for EF welding.

Following the Best Practice steps in POP001 is the best tip for achieving quality electrofusion welds.

This guide has plenty of easy to understand diagrams and documents all the steps and measurements you need for successful electrofusion.