PLASSON seals the deal with a clever tweak

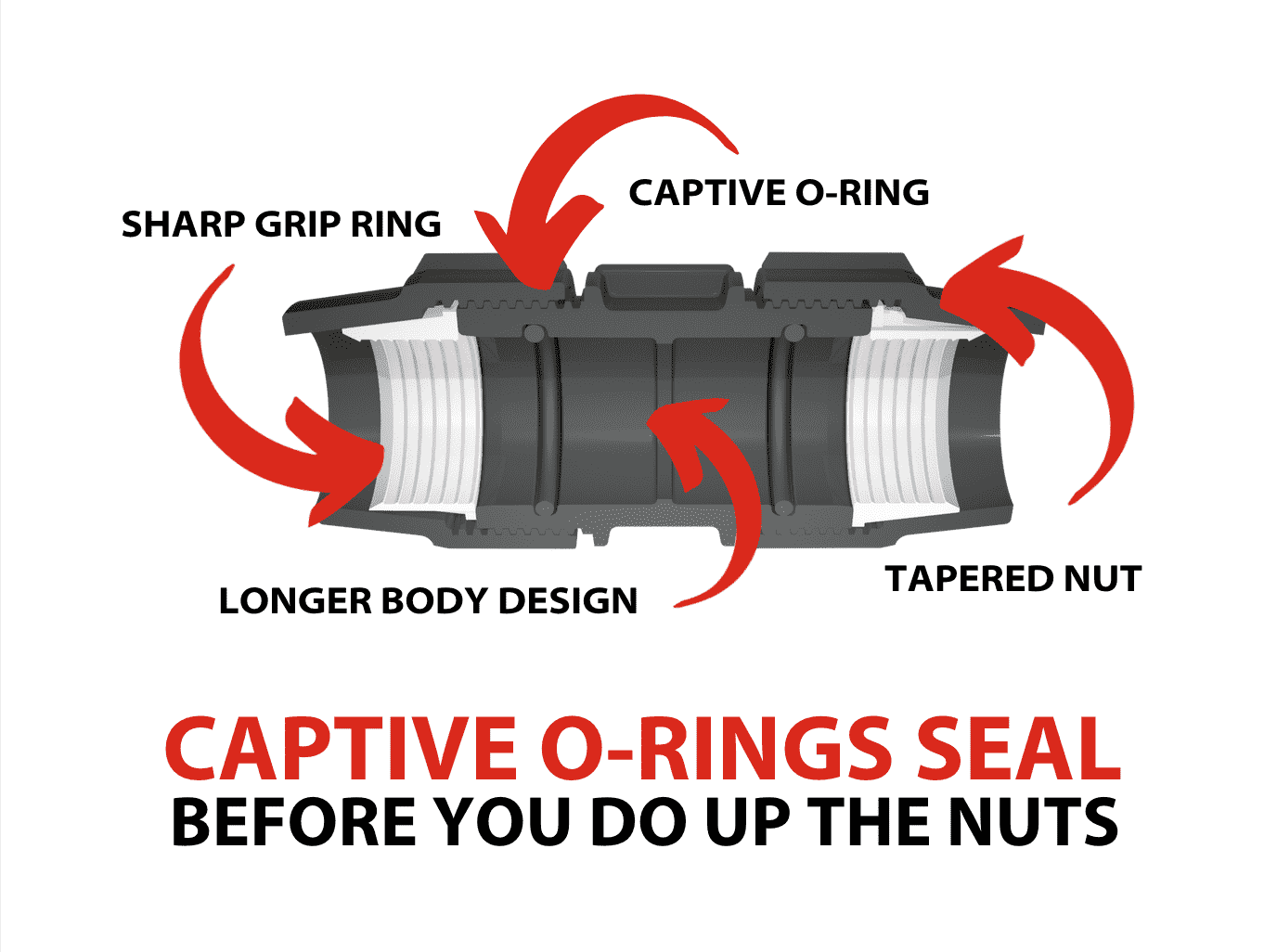

PLASSON took the original O-ring from 1896 and did something simple but clever with it. By placing the O-ring into a special groove machined into the inside of each fitting, the PLASSON O-ring is always in the optimum position for sealing.

This innovative design means the fitting seals water-tight as soon as the pipe passes through the O-ring. With PLASSON compression fittings, you only tighten the nut to prevent the pipe and fitting from moving apart, or blowing out, under pressure. The design also means the O-Ring can’t fall out and be damaged, contaminated or lost during installation.

The O-ring is a donut-shaped ring (technically, a toroid) with a circular cross section made from different elastomers.

PLASSON compression fittings can have Nitrile NBR O-rings or EPDM O-rings, which has a better chemical resistance than NBR, or Vitron seals, which offer better chemical resistance than EPDM.

The name Viton is a trademark and refers to fluorocarbon O-rings, or FKM/FPM for short. This material has an excellent tolerance for high temperatures, resistance to oils, fuels and hydraulic fluids as well as aromatics and solvents.

O-rings seal by mechanical deformation (caused by compression) which creates a barrier to a fluid’s potential leak path between two closely mated surfaces.

Applying fluid pressure pushes the O-ring against the groove wall on the low-pressure side, increasing the sealing force.

At higher pressures, the O-ring deforms to a “D” shape, increasing the contact area further.

PLASSON’s distinctive black poly pipe fittings includes small 16mm and popular residential plumbing fittings at 20mm, 25mm and 32mm right up to large 63mm couplers for civil water and waste water pipelines.

PLASSON compression fittings are easy to install – just take a look at our install video:

It may have mechanical roots but high tech O-rings, like those with elastomers filled with nano-carbon and nano-PTFE, are future focused. Carbon nanotubes are also being used in electrostatic dissipative applications and nano-PTFE is used in ultra pure semiconductor applications so the humble O-ring is sealing a front-row seat in the future.

ABOUT US

Over the last 60 years PLASSON has grown into a global team of over 2,000 talented experts.

We have built a reputation for product, service and support through hard work, innovation and passion.

PLASSON is engineered to deliver.

WAREHOUSES

Melbourne: 7.30am-4pm

25 Business Park Drive

Ravenhall VIC 3023

Brisbane: 7am-4pm

49 Distribution Street

Larapinta QLD 4110

Perth: 7am-3.30pm

8 Tacoma Circuit

Canning Vale WA 6155

CONTACT DETAILS

All Queries

1300 752 776

Sales Email

[email protected]

Head Office

Suite 3, 2 New McLean Street,

Edgecliff NSW 2027

GOT QUESTIONS?

Whether you need to know about installation, application, size range or product codes, our team are here to help on 1300 752 776

How PLASSON engineered a fitting to be “O” so reliable

How PLASSON compression fittings work is a bit of a yarn that starts way back in 1896. Unless you are a trivia junkie, it will probably come as news that one of the most critical precision mechanical components ever developed was patented on May 12, 1896. That was when a Swedish patent for the O-ring was awarded to J.O. Lundberg. Niels A. Christensen was granted a US patent for his O-ring design in 1937.

Like all good ideas, it came to the attention of some pretty big players. The O-ring quickly became the standard seal for hydraulics in the military. The top brass set out the standard sizes and basic design guidelines that remain in use today.

The humble O-ring delivers a reliable seal through compression and that is why PE pipe joiners that seal via O-rings are described as compression fittings.