Understanding poly pipe and the right joiners for your job

This industry is pumped full of letters and numbers – like SDR11, HDPE, PE100 and PN16. There is handy information in those codes. And, when it comes to the different grades of PE, or polyethylene, the benefits of what each one delivers is in the detail.

PLASSON is a world-leading manufacturer of the black fittings that connect different grades of poly pipe. Our fittings connect pipes using compression, where a fittings with nuts and O-Rings are used to create a watertight seal that can also be undone and reconfigured if required, threaded fittings that do up by being screwed into place and also electrofusion fittings that connect polyethylene pipelines permanently, which is where heat is applied via a special poly welding machine to fittings which then melts and fuses plastic from the pipe and fitting together.

Poly pipelines are strong, light-weight and corrosion-free. Polyethylene pipe is also 100% recyclable at the end of it’s functional life. There are many upsides to installing poly pipelines but some of the terms used in the industry can make the options sound complicated.

Here’s some handy information to help you understand what does what with which, why and how!

PE Pipe

Most common PE pipelines are made from PE100. Polyethylene (poly, or PE) pipe is used to make different types of piping: low density, rural and metric, and they all have different uses and specifications.

Common sizes for low eensity pipe are 13, 19 and 25mm. It is generally rated at 40-50psi. Low density pipe does not normally have a stripe.

Rural poly pipe remains popular with farmers and irrigators. It is often referred to as B Class poly and generally has a green stripe. Rural pipe sizes are expressed in inches. It is rated to 800kpa (115psi).

There are several classes within the metric pipe range each with a different pressure rating and wall thickness. It is often used in domestic plumbing with mains supply. Metric pipe ranges from 16mm up to 110mm and beyond (16, 25, 32, 40, 50, 63, 75, 90 and 110mm) and has a blue stripe with pressure ratings of 800kpa up to 1600kPa (PN8, PN10, PN12.5, PN16).

Poly Pipe Sizes

If you aren’t familiar with poly pipe, sizing can seem confusing as the nominal size has little resemblance to the actual measured size. Low density and rural poly pipe are measured by their inside diameter but metric poly pipe is measured by the outside diameter. For example, 1” rural poly pipe has an OD of 29mm and an ID of 24mm, while 25mm PN12.5 metric pipe has an OD of 25mm and an ID of 20mm.

Friction

Friction is the resistance that a pipe imparts on water as it moves through it. An good way to think of this is like the resistance you feel when you put your hand out the car window. When you are parked there is no resistance but when you move the resistance increases and the faster you go, the more resistance you experience.

The faster water moves through a pipe, the more resistance there is. The resistance is called pressure loss or pipe friction. For example, if moving 100L per minute through both a 2” pipe and a 3/4” pipe, the water will be moving faster in the 3/4” pipe – and hence there will be more pressure loss (friction) in the 3/4” pipe.

Flow

It makes sense that water flows quicker through a 1m hose than a 1000m hose. Friction works on a per meter basis. So, the smaller the pipe and the longer the pipe, the more friction there will be and thus less flow.

Fittings

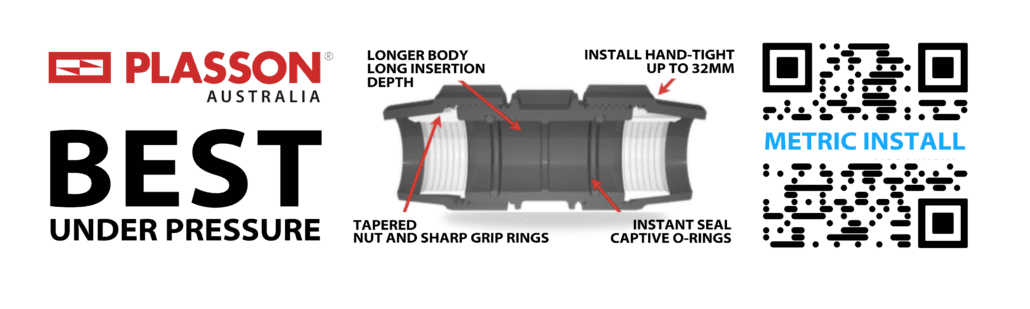

PLASSON metric compression fittings are most often used with blue and lilac stripe poly pipe. They are PN16 rated and are suitable for both high and low pressure. They are also somethings called mechanical compression fittings and they are engineered from high quality materials that are corrosion resistant, UV stablised, light-weight and strong.

PLASSON’s metric compression range features innovative captive O-rings and long body design to help ensure leak-free pipelines for residential and commercial plumbing as well as civil and industrial applications.

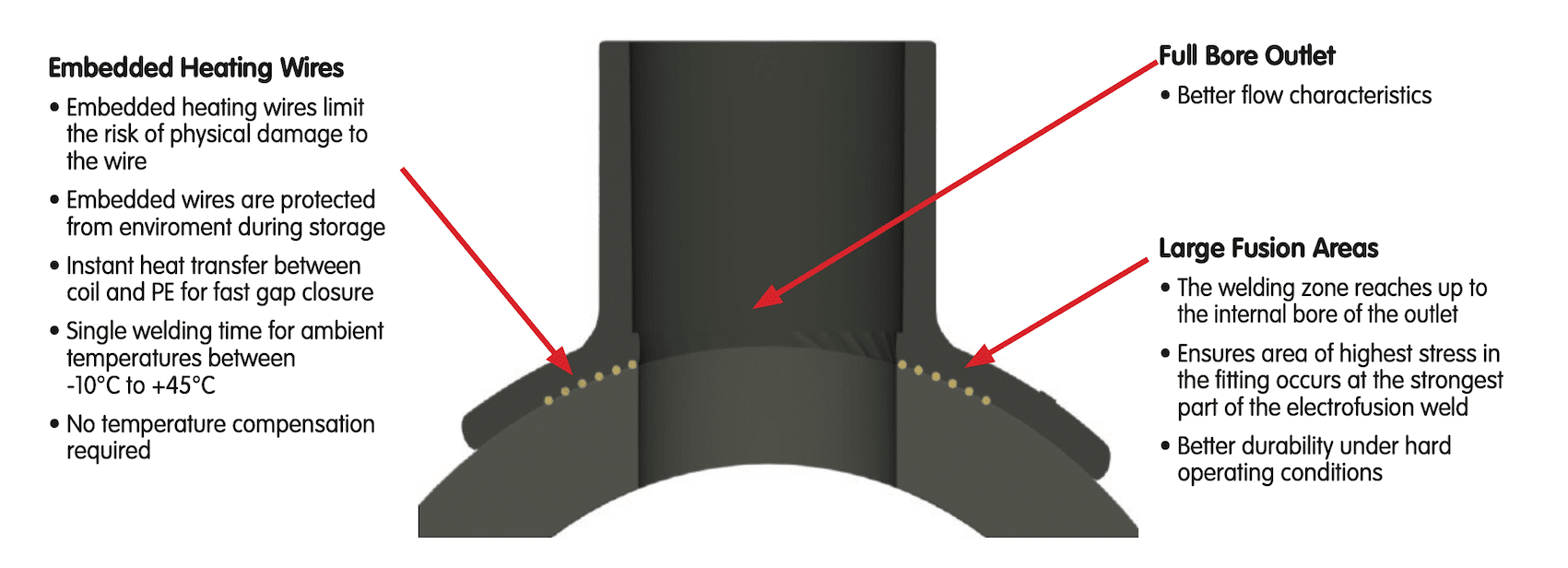

Electrofusion couplers are used to join yellow stripe pipe for gas installations as well as some red stripe fire mains installations and blue stripe civil water and waste water pipelines. They are installed using special welding control boxes which apply current to special EF fittings. Embedded wires in the fitting heat up and cause the plastic in the fitting and pipe to melt and mix so that they become permanently fused together.

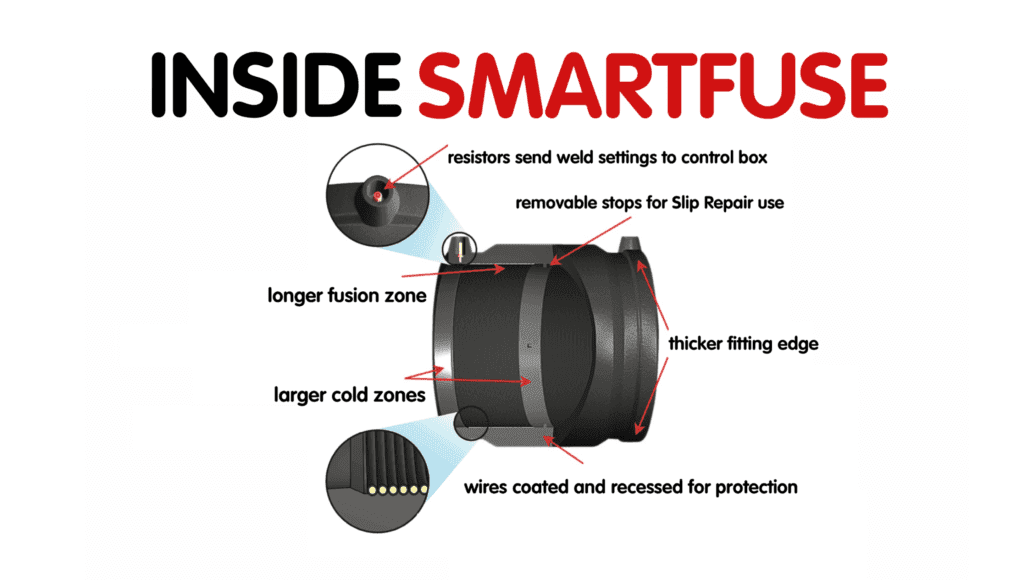

PLASSON has a reputation for manufacturing innovative electrofusion fittings. The PLASSON SmartFuse system builds on this with a fully guided installation and recording process to simplify EF welding.

All SmartFuse fittings have smart resistors built in that feed the correct weld parameters into PLASSON’s SmartFuse EF welders as soon as the fitting is connected. No manual entry and no scanning means it’s not only faster to set up each and every weld but the potential for costly input errors is eliminated.

PLASSON’s rural range is designed to connect green stripe poly pipe and will suit both metric and imperial sized pipe. These rural compression fittings go on the pipe and seal watertight instantly with no special tools needed for installation.

Instant Sealing

PLASSON’s captive O-ring creates a seal before you even tighten the nut. And you don’t need any special tools to install our fittings. Just do the nuts up firmly by hand and the job is done.

Instant Sealing

PLASSON’s captive O-ring creates a seal before you even tighten the nut. And you don’t need any special tools to install our fittings. Just do the nuts up firmly by hand and the job is done.

FlexiblePLASSON rural poly pipe joiners can also be converted to connect to metric poly (blue line), PVC, steel, and copper pipes. The long body on PLASSON rural compression fittings ensures the seal will not be affected by bending loads or ground movement.

All PLASSON fittings exceed the pull-out requirements of Australian Standards making them the first choice for submersible bore jobs.