COMMERCIAL | POLYWELD NZ

CASE STUDY

Plasson Live Tap Solution for

Critical Wastewater Pipeline

Project

Polyweld NZ was selected as the preferred HDPE welding contractor for a major pipeline installation, involving:

- 20km of 355 SDR13.6 PN12.5

- 7.5km of 125 SDR13.6 PN12.5 & 125 SDR9 PN20

In addition to welding services, Polyweld NZ also supplied critical fittings, including full-face flanges, equal tees, stub flanges, backing rings, and saddles. The project was designed by Beca and was our client’s largest pipeline project to date.

Results and Impact

The live tap connection was completed safely, efficiently, and fully compliant with AS/NZS 4129:2020. The innovative approach delivered substantial benefits for the client and community:

Significant time and cost savings

by avoiding a full pipeline shutdown.

No interruption to wastewater services

for more than 31,600 Rolleston residents.

Environmental protection

with minimal excavation and reduced risk of wastewater discharge.

Successful 355 live tap

the first for Polyweld NZ, completed with precision and confidence.

Seamless collaboration

between Polyweld NZ, Plasson, and Asmuss to deliver a future-proof connection.

Challenge

A critical element of the project was connecting the newly installed DN355 PE pipeline to the existing DN630 wastewater line, which serves over 31,600 residents in Rolleston.

The original design called for a 630×355 LS Reducing Tee, requiring an electrofusion weld into the live 630 main. However, shutting down this pipeline was not an option.

The line operates under continuous heavy load, and a shutdown would have demanded around 20 sucker trucks working non-stop to manage wastewater flows, a costly, high-risk and impractical solution.

“Having a highly specialised team of welding technicians meant we could respond at short notice and deliver a seamless, successful outcome for our client.”

“With the advancements in technology and the support of trusted partners such as Plasson and Asmuss, Polyweld NZ is proud to set industry standards in technical support and product excellence.”

“This project is a testament to the value of experienced professionals and reliable partnerships in achieving outstanding results for critical infrastructure projects.“

Leighton Read | Operations Manager, Polyweld NZ

Solution

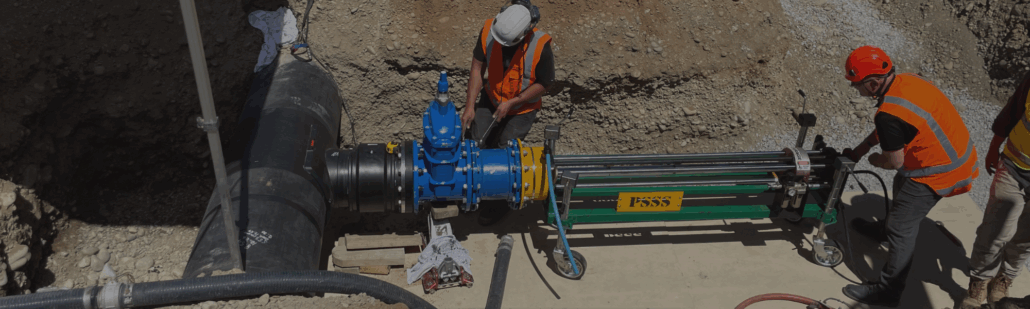

Plasson Top Load Branch Saddle

A 630×355 top load saddle was installed instead of a traditional reducing tee. The saddle design allows for a full pressure test before coring, ensuring weld integrity. Once cored, the cold zone is removed, leaving a solid internal wall and a connection as strong as, or stronger than, the host pipe.

Electrofusion Coupler & Slim Flange

The branch was completed using a Plasson electrofusion coupler and a full-face, full-bore PE slim flange for the valve connection. This eliminated the risks associated with PE-to-DI flange connections and provided maximum strength.

Live Tapping

The existing 630 wastewater pipeline was successfully live tapped, avoiding the need for any shutdown.

Training & Support

Plasson provided pre-weld training and on-site support. Combined with Polyweld’s field expertise, this gave the asset owner complete confidence in the solution.