HDPE pipe fittings help connect HDPE pipe together. PLASSON fittings can join HDPE pipe in different ways: electrofusion fittings join pipe permanently through fusion; metric compression fittings seal through an internal O-ring being compressed to form a seal between the fitting and the pipe; and BSP threaded fittings join pipe through threaded connections.

There is a surprisingly vast range of poly pipe compression fittings. Even the most familiar options, like couplers, tees and elbows, have a range of reducing and connection options that can take some time to understand.

While pipe fittings or connectors attach one pipe to another in order to lengthen the run or change the flow direction in a plumbing system, there are also lots of clever fittings that do so much more to make plumbing life easier. They can combine, divert or reduce the flow of the water supply. They can monitor flow or stop it, reduce pressure and provide outlets for sampling.

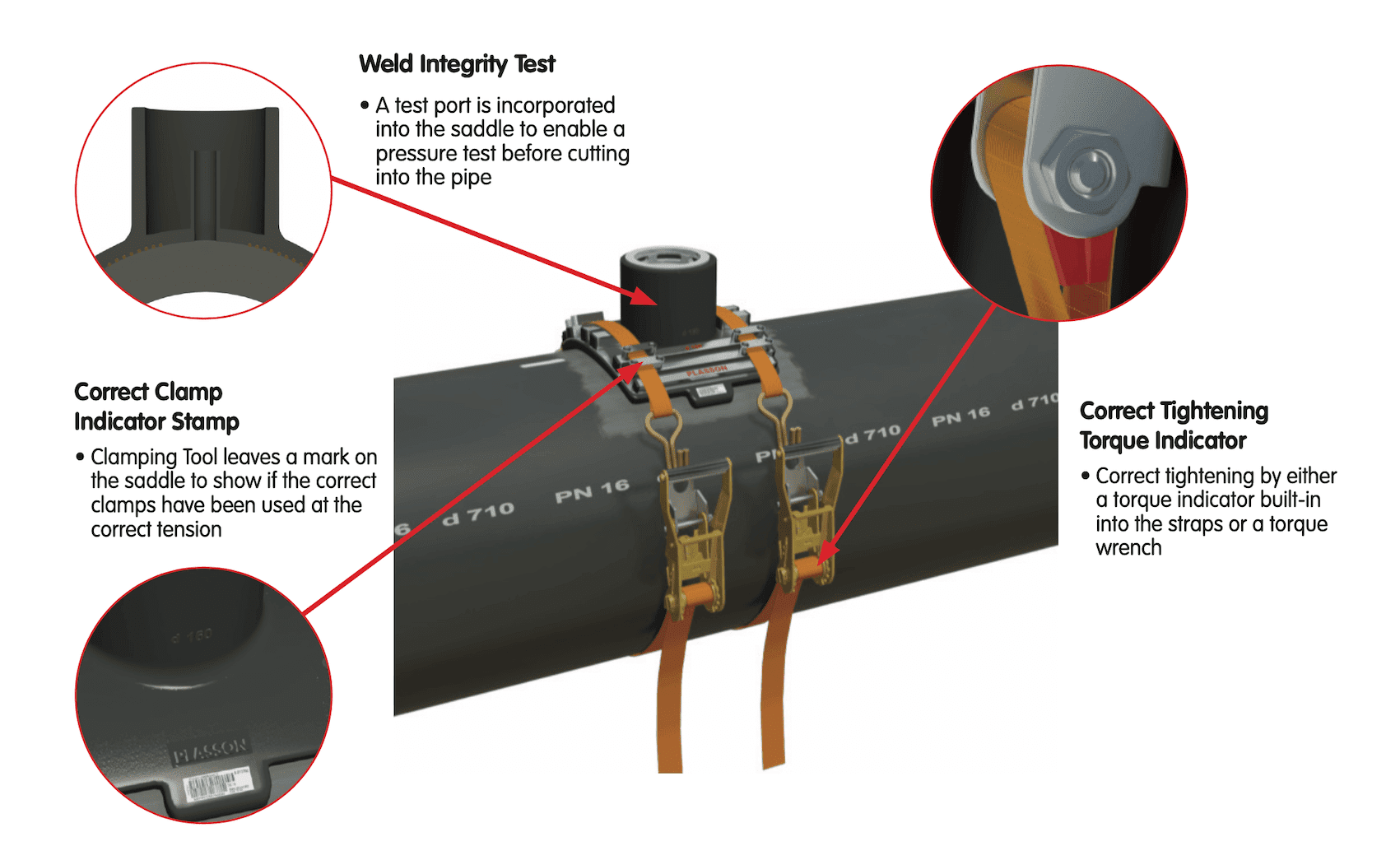

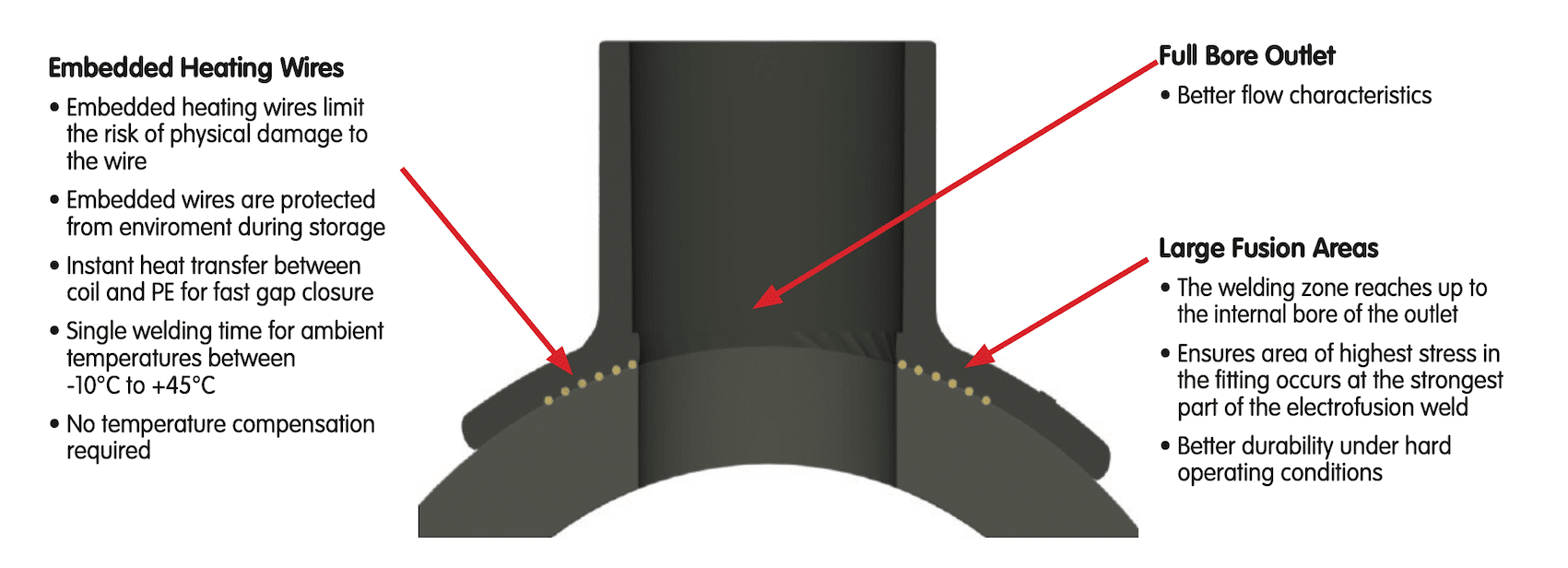

PLASSON compression fittings have a number of unique features that help deliver leak-free connections and reliable, long-life PE pipelines.

Compression fittings come in a range of standard sizes. PLASSON compression fittings start small for domestic plumbing at 16mm, 20mm, 25mm and 32mm and continue up to civil and industrial sizes like 40mm, 50mm, 63mm and right up there to above 1000mm.

All PLASSON compression fittings seal the instant they go on the pipe due to an innovative O-ring design. The O-ring is held captive in the body of the fitting in a specially designed groove. This simple piece of engineering means the O-Ring can’t fall out, get contaminated or become easily damaged like other compression fittings.

While most have openings of the same size on each end, some fittings are designed with different-sized openings and serve as the transition from one size pipe to another. The following briefly explains some of the different PLASSON fittings, where and how they are used.

To see the full range of PLASSON metric compression poly pipe fittings click here…

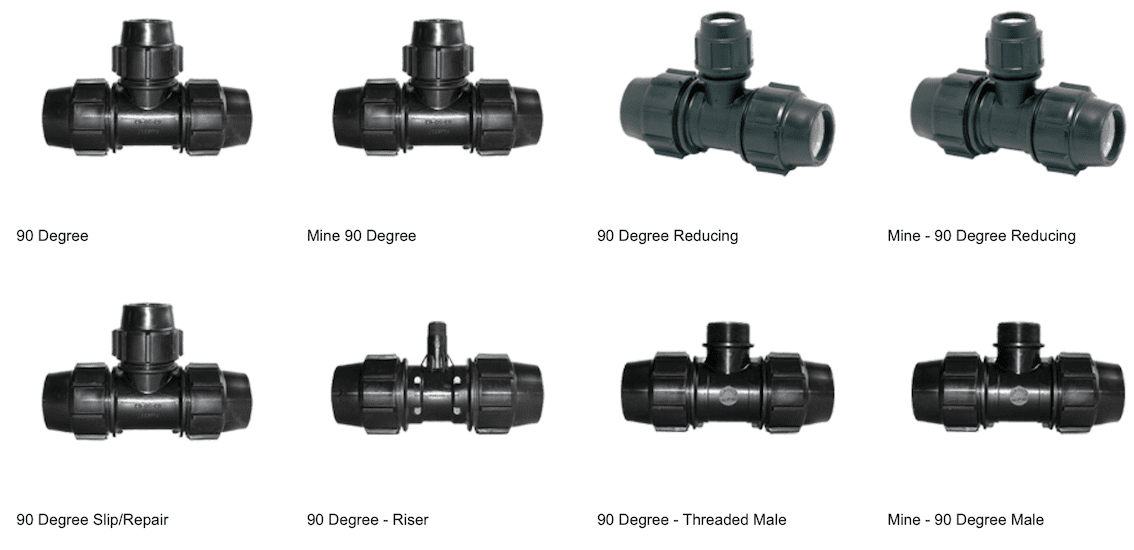

Tee Fittings & Wye Fittings

Tees and wyes are used to connect three pieces of pipe. Tees can have one inlet and two outlets at 90-degree angles in the shape of a “T” and are used to split a supply line, or they can combine two lines into one outlet. You often see tee fittings connected to potable water supply lines. A wye is shaped like a “Y” with the two inlets coming together at roughly 45-degrees into a single outlet in drain applications.

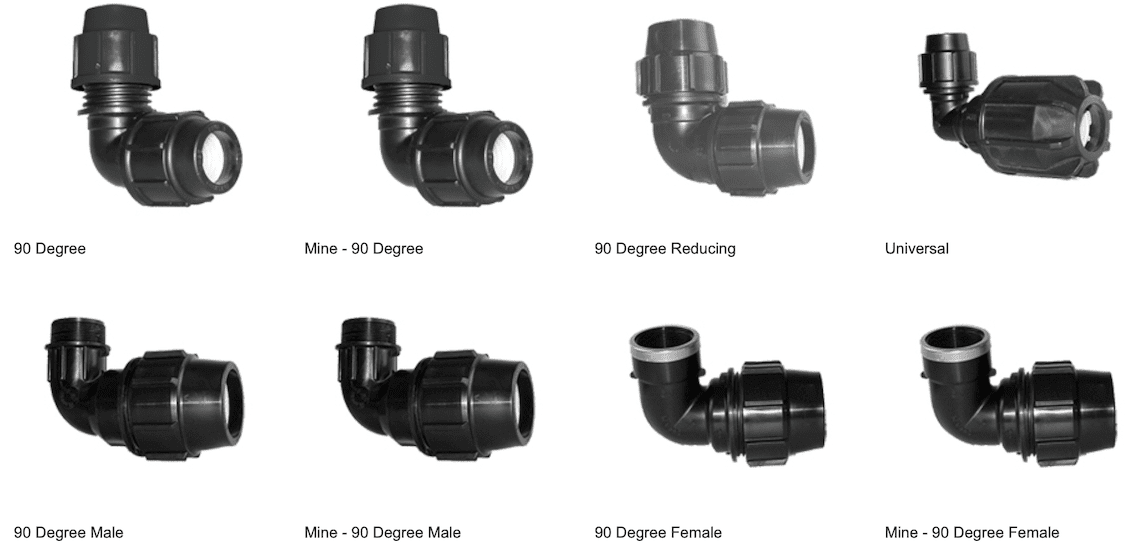

Elbow Fittings

Elbows change the direction of flow between two pipes. Common elbows have 90-, 60-, 45- and 22 ½-degree bends and are used to make a turn. They can be joined together to move around obstructions in a pipe run.

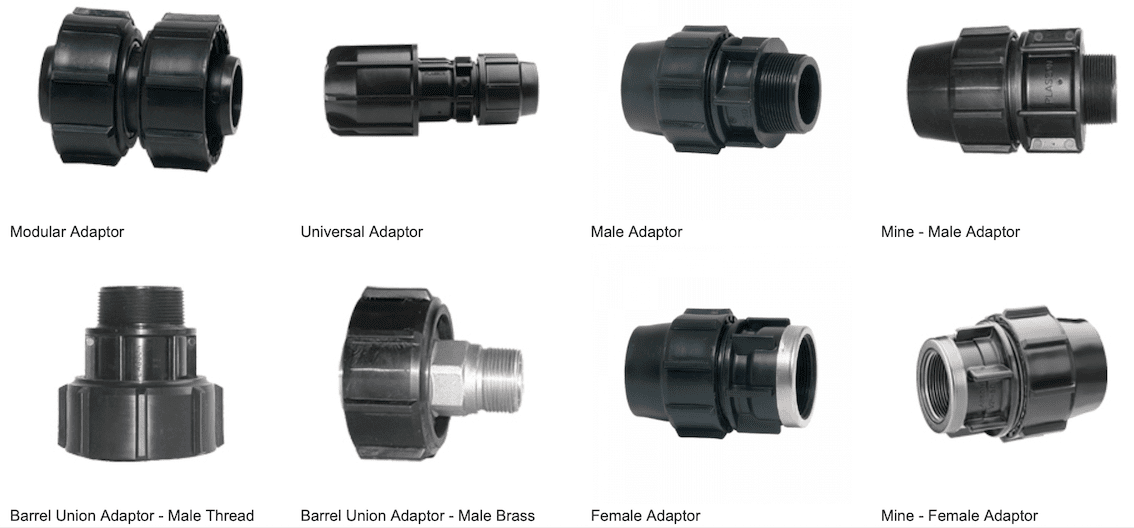

Coupling & Adapter Fittings

Pipe couplers slip over the outside of two pipes to connect them. A coupling can be a reducer, or reducing coupling, meaning they reduce flow by joining a larger pipe to a smaller size. Adapters are used when connecting two pipes of different types. For example, an adapter could be fitted on the end of a plain pipe to allow a threaded connection at the other side of the adapter, or to connect poly pipe with another pipe material, like copper.

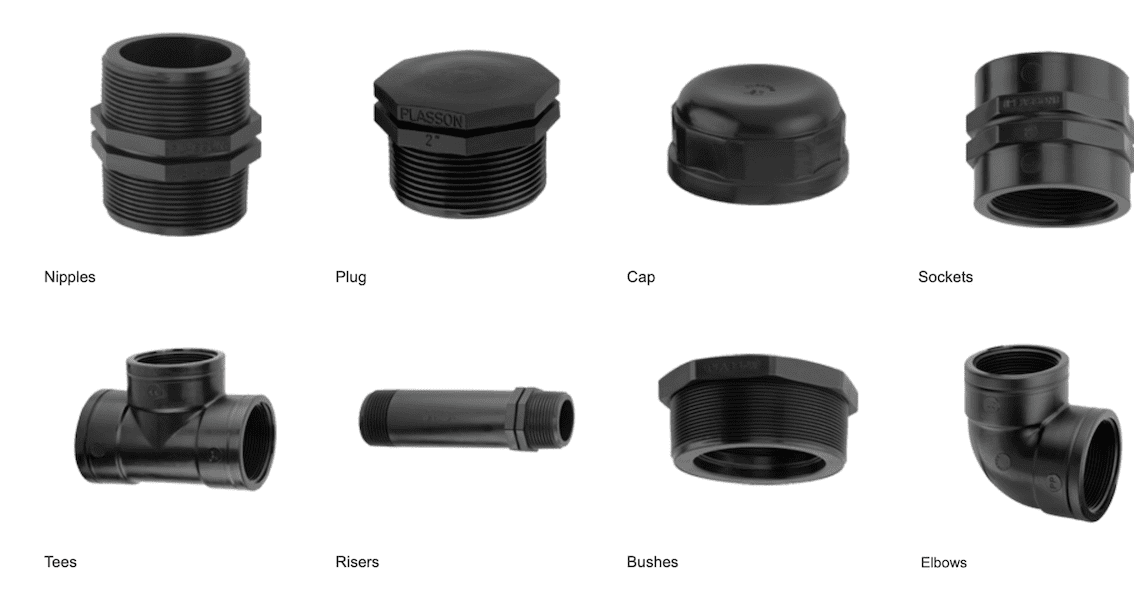

Bushing Fittings

Bushings, sometimes called reducer bushings, are used for connecting two pipes of different sizes. The larger diameter of the bushing fits inside of the larger pipe. The smaller pipe is then inserted into the smaller end of the bushing.

Flange Fittings

A flange is a flat, round fitting that creates a tight seal with bolts or clamps. They are used when pipes pass through walls, ceilings and floors. They are also used in electrofusion installations to connect valves to main lines.

Cap Fittings

A cap fits over the end of a pipe to stop the flow of water or gas. These fittings can be used for the permanent termination point of a pipe or used temporarily to cut off supply during a plumbing or pipeline project.

Plug Fittings

Plugs used at the end of a pipe to seal the opening, similar to a cap. The difference is that a plug fits into the threaded pipe opening to make the seal while caps fit over the opening. They are commonly found at cleanout locations for sewer systems.

Nipple Fittings

Nipples are short sections of pipe that are male-threaded at each end and used for connecting two female-threaded pipe ends or fittings.

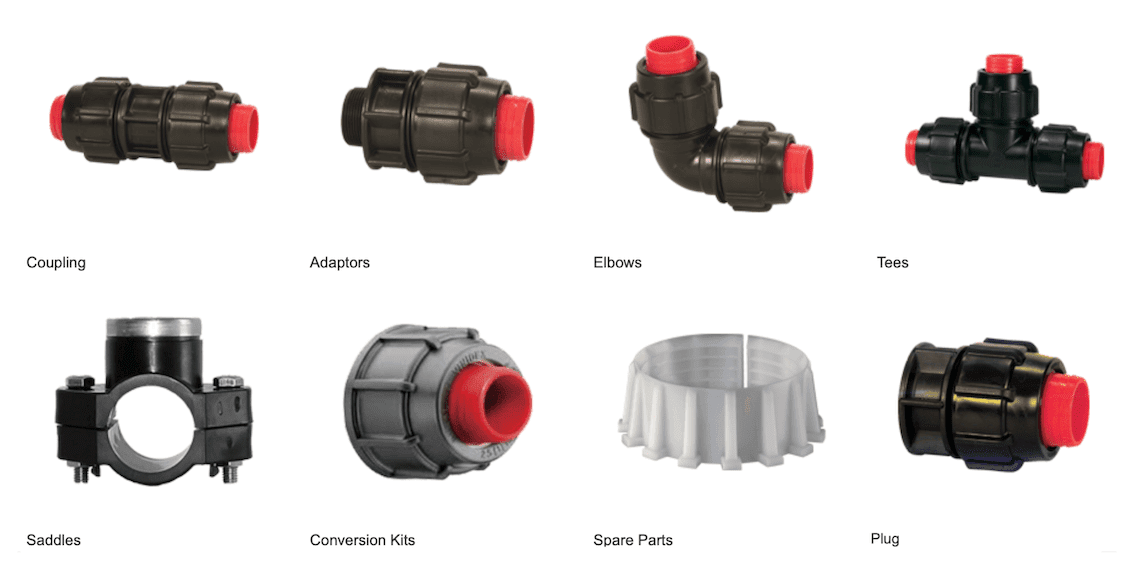

Ag Pipe Fittings

Agricultural pipe is widely used for stock watering, water mains, irrigation systems and bore water reticulation. PLASSON rural couplings and clamp saddles are specially designed to connect imperial-size polyethylene pipes from ¾” to 2″. The range is compatible with PELD, PEHD, PE40, PE80 and PE100 pipes complying with AS/NZS 4130. PLASSON’s special red barbed inserts fit a range of pipe dimensions so that ag pipe can be easily connected without the need for any tools.

The PLASSON range includes solutions for most plumbing situations. You can take a look at the catalogue for the full range here….