SmartFuse might just look like a product name etched into PLASSON fittings but it represents our commitment to high quality, reliable electrofusion welding – for installers, asset owners and those who rely on what comes down the pipes.

Over the last 50 years, metallic pipelines have been increasingly replaced by thermoplastic systems such as polyethylene, or PE. This is due to the significant advantages of PE like environmental resistance, especially corrosion, low maintenance demands and ease of installation; PE pipelines can even endure earthquakes.

Most newly installed water, sewage and gas distribution pipelines will be PE pipelines and they are increasingly being joined by electrofusion or EF. Electrofusion is considered the most reliable method of joining gas-carrying pipes. In fact, the gas industry was where EF was first used since gases can be hazardous if not secured properly.

THE KEY TO RELIABLE LONG-LASTING INFRASTRUCTURE

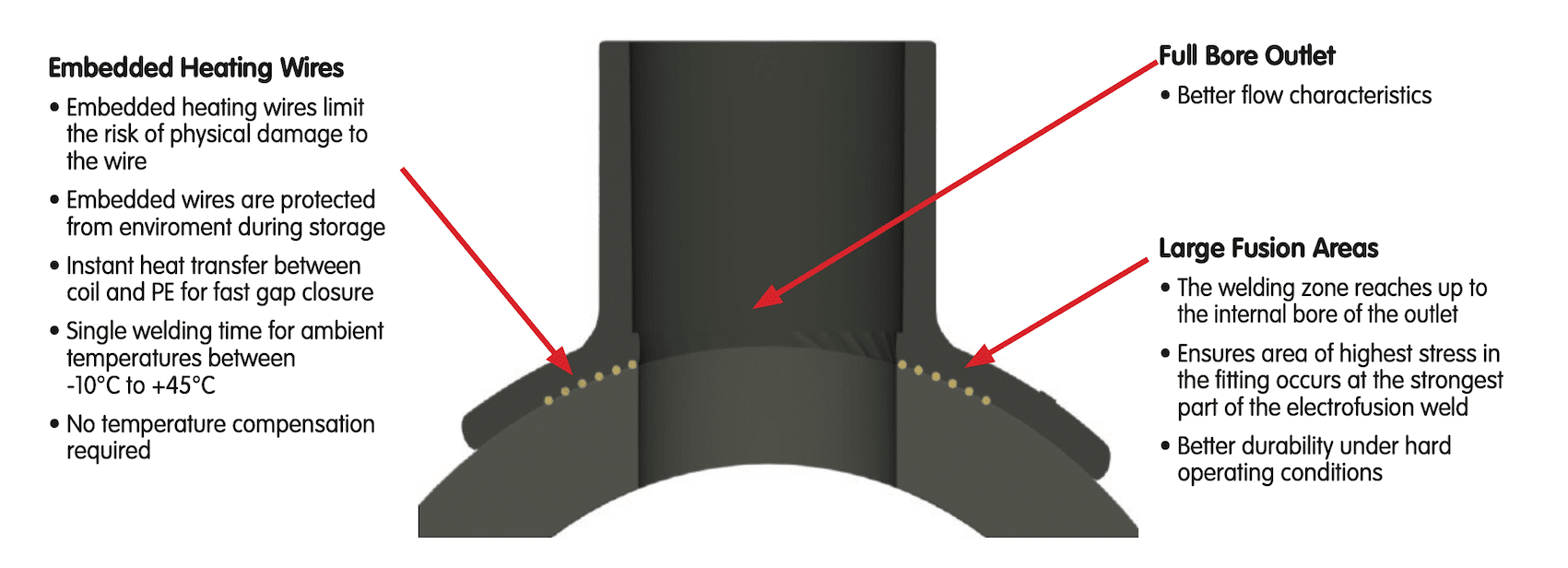

Given the obvious need for reliable, long-lasting infrastructure, developing high quality electrofusion fittings and systems for installation has been a PLASSON priority.

With specialized control boxes, reliable electrofusion fittings and precision tooling, PLASSON’S electrofusion range helps deliver better electrofusion welding.

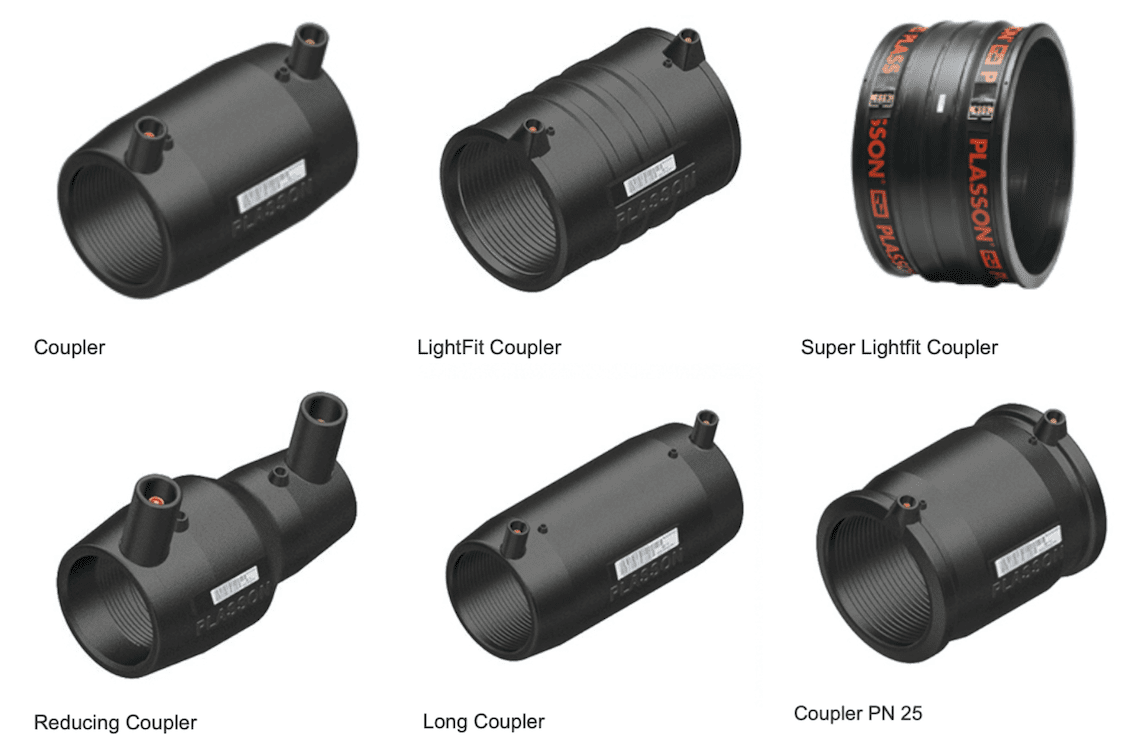

PLASSON electrofusion fittings range from options for small diameter poly pipe, like 16mm and 20mm, to options for large diameter civil water and waste water pipes at 400mm to 800mm, 900mm and even 1000mm.

Electrofusion delivers reliable results on small and large diameter poly pipe. EF is also suitable for pipes with a small diameter since it does not shrink the inner diameter of the pipe. So whether welding a 32mm to 1/2″ brass transition fitting or a saddle onto 63mm blue stripe pipe, PLASSON electrofusion fittings are engineered to deliver quality electrofusion welds.

TECHNOLOGY THAT WORKS FOR YOU

The SmartFuse system offers fully automated welding and, when paired with the SmartFuse app, delivers image capture and cloud storage for all weld records. With the click of a button, weld data is stored and accessible, anywhere, anytime.

The SmartFuse app helps lower operational costs, reduces mistakes and joins can be easily traced and identified via the GPS data that is part of every SmartFuse weld record.

PLASSON is committed to innovation in the EF field. As a future focused company, we are continually working to improve what we offer, to facilitate better electrofusion welding, deliver enhanced asset management and asset visibility.

Leave a Reply

Want to join the discussion?Feel free to contribute!